Specifications for the Interpac Corrugator

BASIC SPECIFICATION

Paper widths

From 700mm to 1250mm

Chop range

From 600mm

Paper weights

Fluting: 80 to 120gsm

Top and bottom liners: 80 to 200gsm

Paper types

Fluting: waste based recycled, unsized and uncoated

Inside and outside liners: kraft, test, clay coated

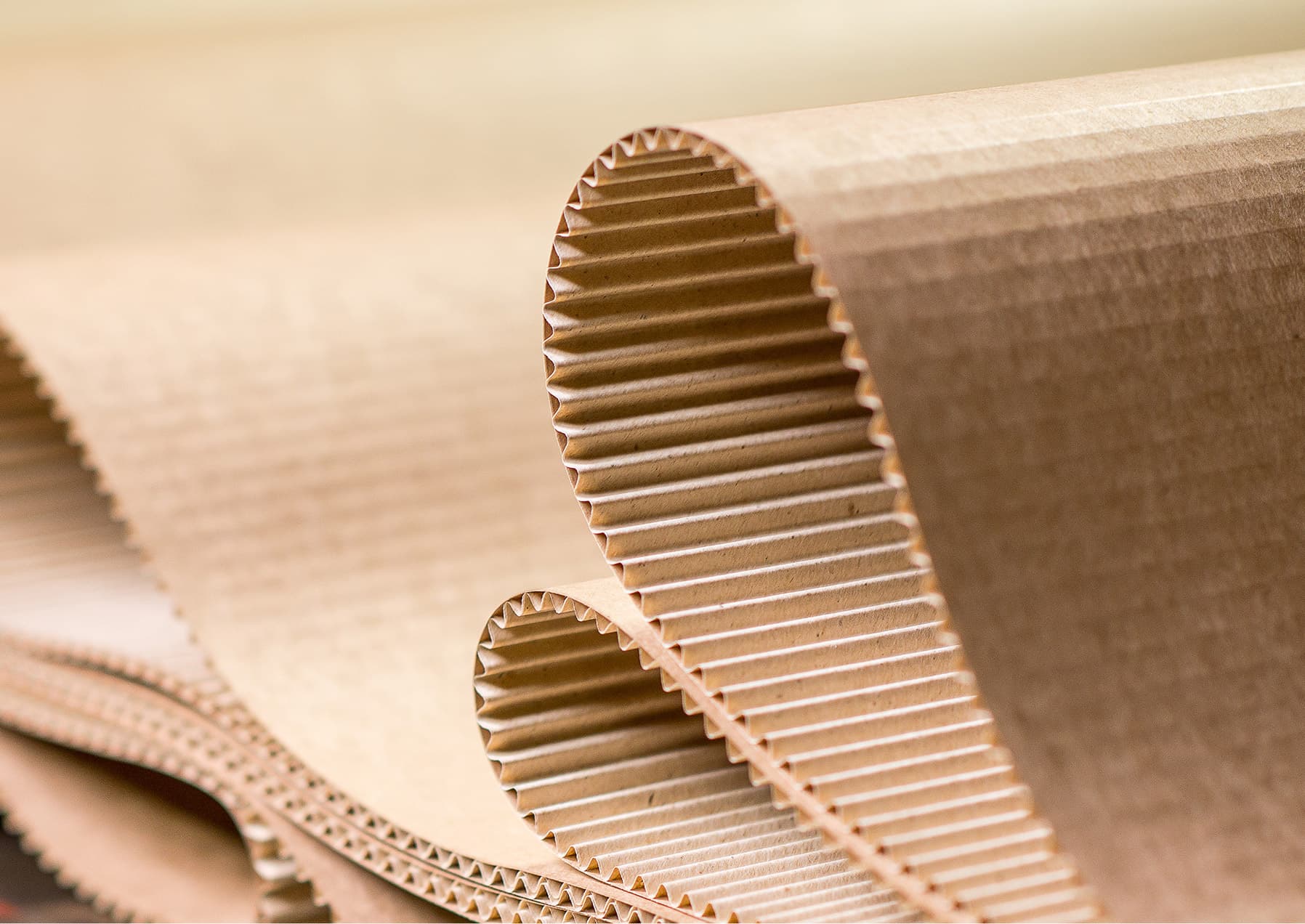

Flute profiles

Our standard flute profiles are:

B flute: flute height: 2.5mm, flute pitch: 6.5mm

E flute: flute height: 1.2mm, flute pitch: 3.6mm

If you require alternative profiles, please discuss this with us

Line speed

50 meters per minute

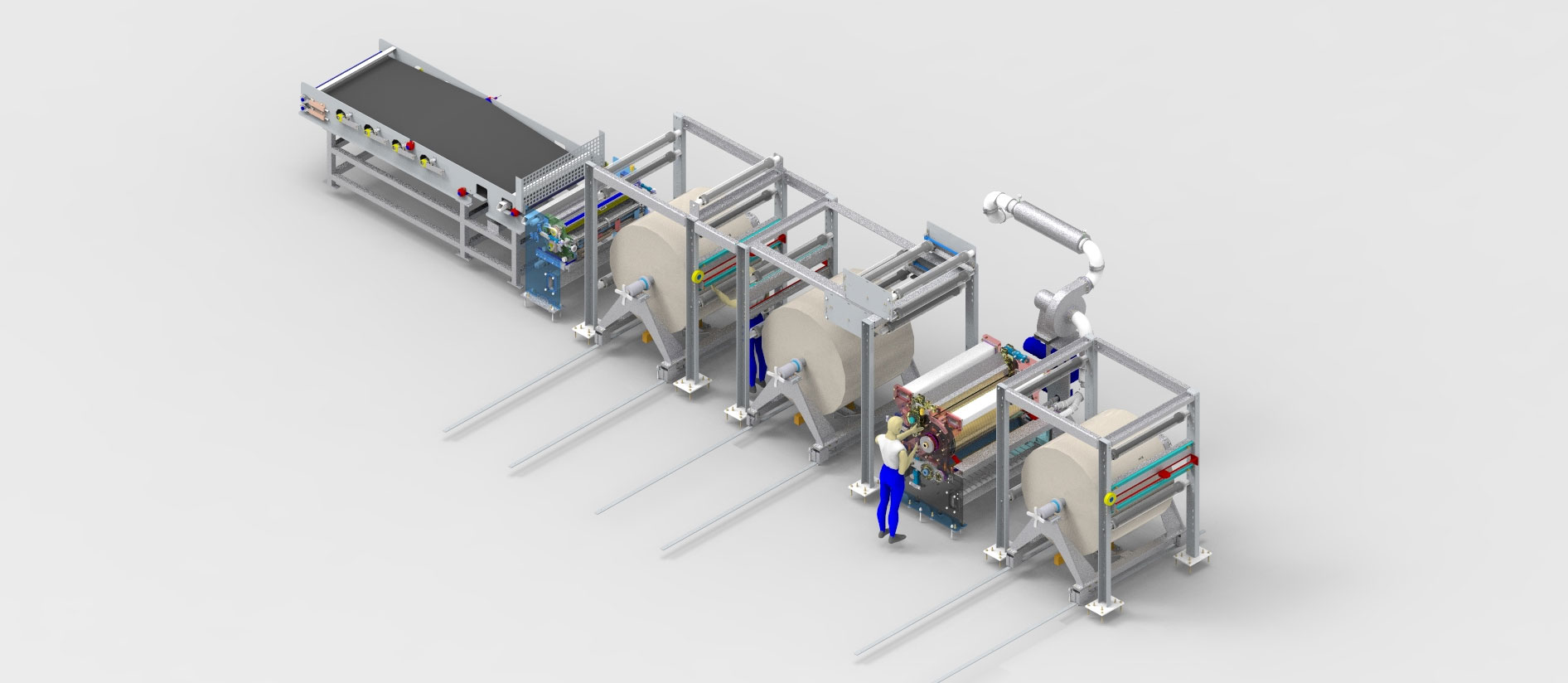

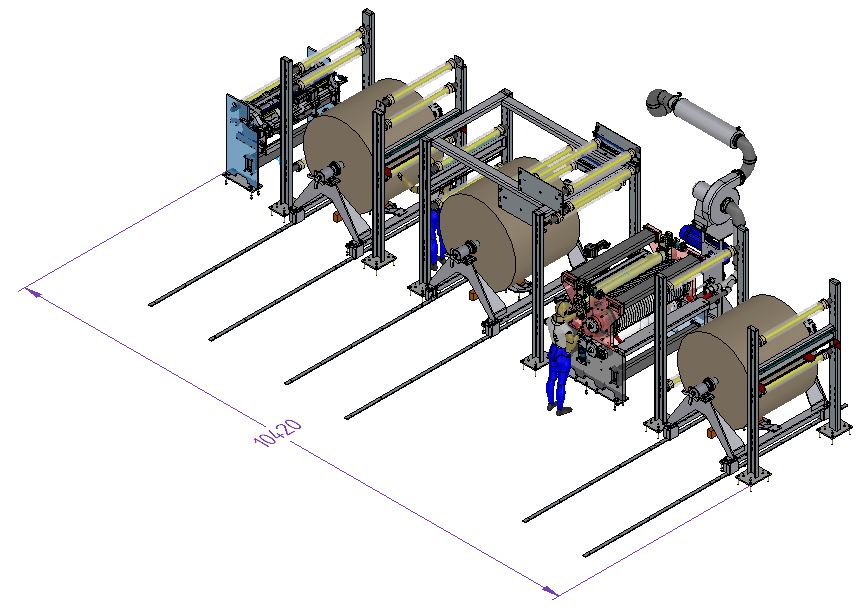

Dimensions:

Length:

Approximately 31m long (includes single facer, double backer, slitter/scorer, cut -o and stacker)

The stack height at this length is 900mm

We can tailor the stacker to your specific requirements and advise you on overall length

Width:

Approx 4m wide (with single sided reel stands (access required one side only)

Approx 8m wide with double sided reel stands (access required both sides)

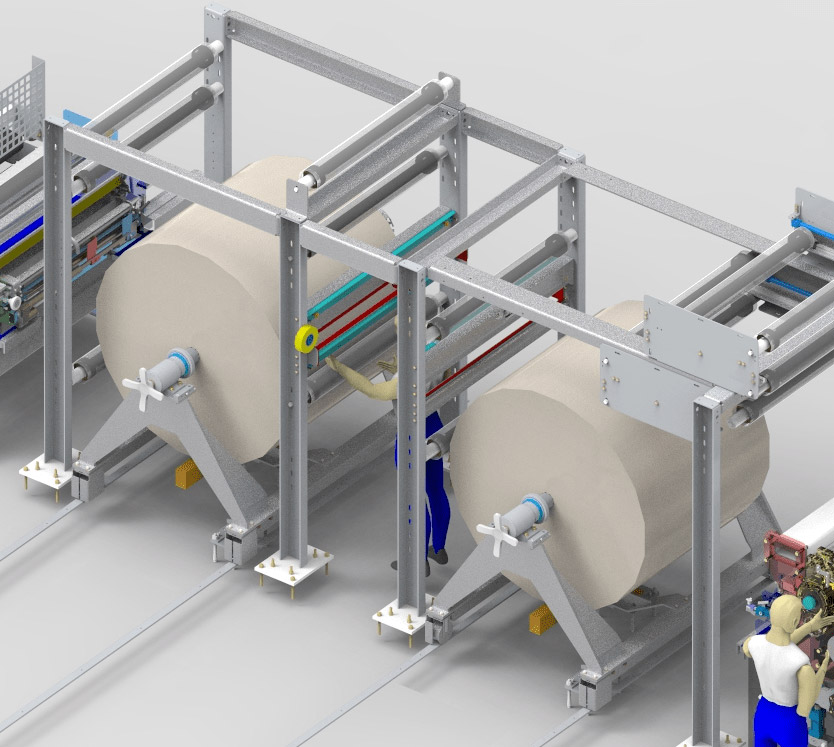

REEL STANDS

- Single or double-sided loading

- With double sided loading production is continuous while the replacement reel is being prepared

- Reel stands slide in and out on wheeled trolleys with a built-in hydraulic drive (op/ drive side)

- No need for floor rails

- Constant automatic web tension control, regulated by (air pressure) brakes. Manual override for web tension in the control panel

- Visual end-of-roll warning

SPLICERS

- Manual cutting / splicing unit with paper retaining clamps

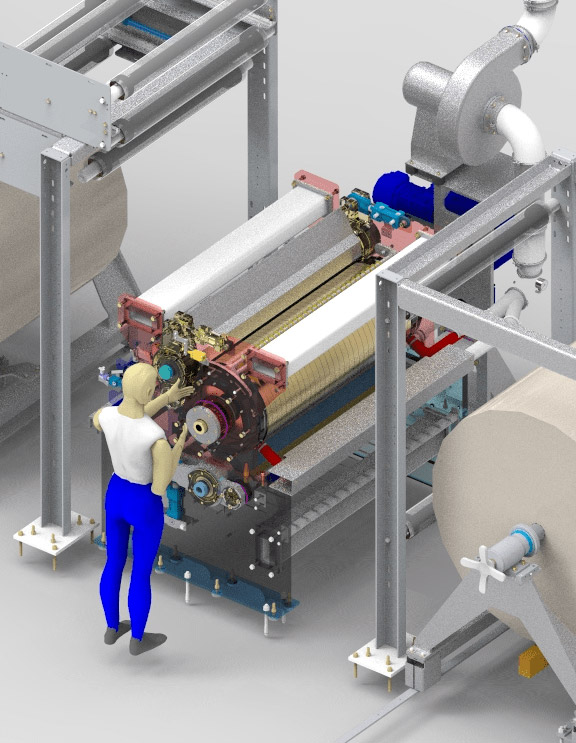

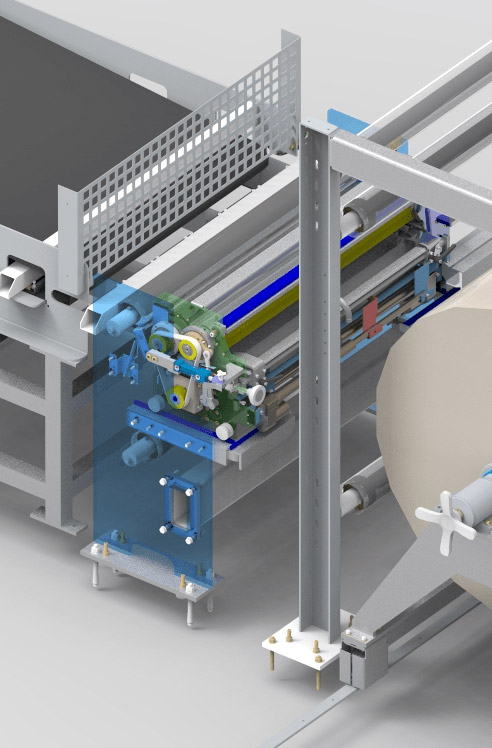

SINGLE FACER

- Quick change flute cassette system

- Hydraulic pressure control for the corrugating roll and press roll

- Vacuum system for the lower corrugating roll

GLUER UNITS

- Glue gap control from control panel for precise glue application

- Automatic glue dam control to follow paper movement with manual over-ride

- Retractable glue unit for easy cleaning

- Water spray nozzles for easy cleaning of the glue unit

- Stainless steel glue pan

- Bronze metering roll scraper

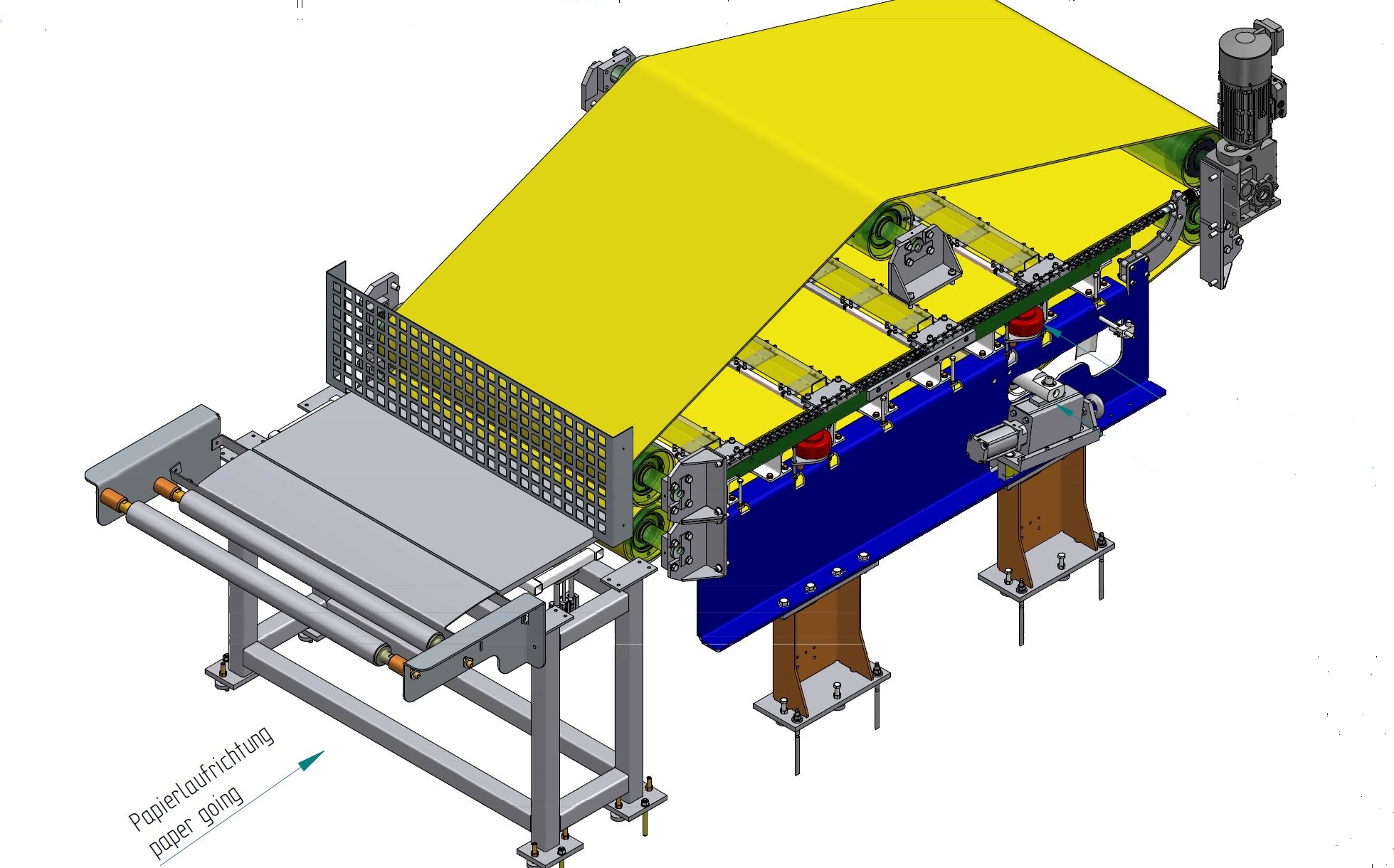

BRIDGE

- Automatic bridge volume control linked to line speed

- Automatic stop before bridge runs empty

- Pneumatically controlled bridge break roll for tension control of the single faced web

- Drying section for the single faced web

DOUBLE BACKER & DRYING SECTION

- Curved heating plate for outer liner

- Heating section to dry the board

- Traction unit with automatic belt guidance system

- Load system to assure board contact with the heating elements

SLITTER (Gold Version)

- No. of scorer tools: max. 4

- Scorer positioning: By hand on a platform above the unit (outside the machine)

- Tool-less click stop adjustment with rotating vernier for accurate positioning

- Allows for preparation of 2nd shaft during production (Gold version only)

- Turn system for scorer shafts: motorised

SLITTER (Gold version)

- No. of outs: max. 2

- No. of knife shafts: 1

- Middle knife: Yes

- Knife system: Blade (bottom) into brush (top)

- Knife positioning: Manual by crank from the outside the machine with vernier readouts for precise positioning

- Manual knife grinding system for sharpening within machine

- Edge trim knives: yes, with chutes

- Maximum 50mm side trim

CUT-OFF

- Single knife

- Chop range: 600 to 2000mm at max line speed

- Cut blade against anvil roll

- Cut o adjustment made from control panel with machine running

STACKER

- Automatic single chamber

- Minimum board length: 600mm

- Maximum board length: 2000mm

- Maximum stack height: 900mm but can be specified by the customer